Calibration Station is a simple and elegant solution for your quality control needs. This tool mounts to walls and allows your employees to check calibration of tools rather than have them visit the quality control room.

Its simple design allows employees to check the calibration of the following tools:

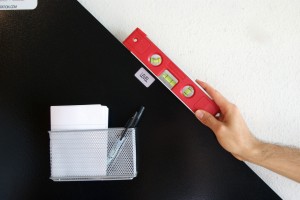

Calibration Station comes with a basket installed for your quality control team to store their decals and pens. When employees are finished validating the calibration of their equipment, they can take a decal and sign and mark the date for the next calibration check up.

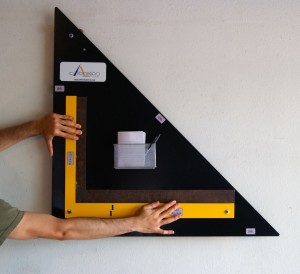

Calibrate Squares

Calibration Station checks calibration of your squares simply. It’s so simple we can’t even describe it, so just look below.

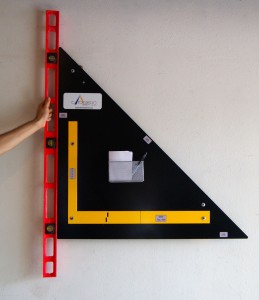

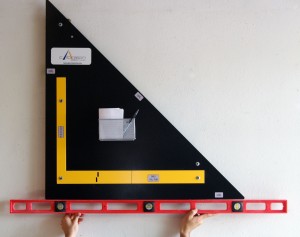

Calibrate Levels

Need to know if your levels are calibrated? Calibration Station can give you the answer. Large, small or 45 degree, the station is equipped to check calibration of them all.

Calibrate Tape Measures

Calibration Station easily checks calibration of tape measures. This tool allows you to check by pushing and pulling at the 6 inch mark.

That’s it.

Your quality control team will need to calibrate the station itself. We recommend they do this yearly and instructions on how to calibrate the station are here.